No limits to your ideas

Cellular polyethylene

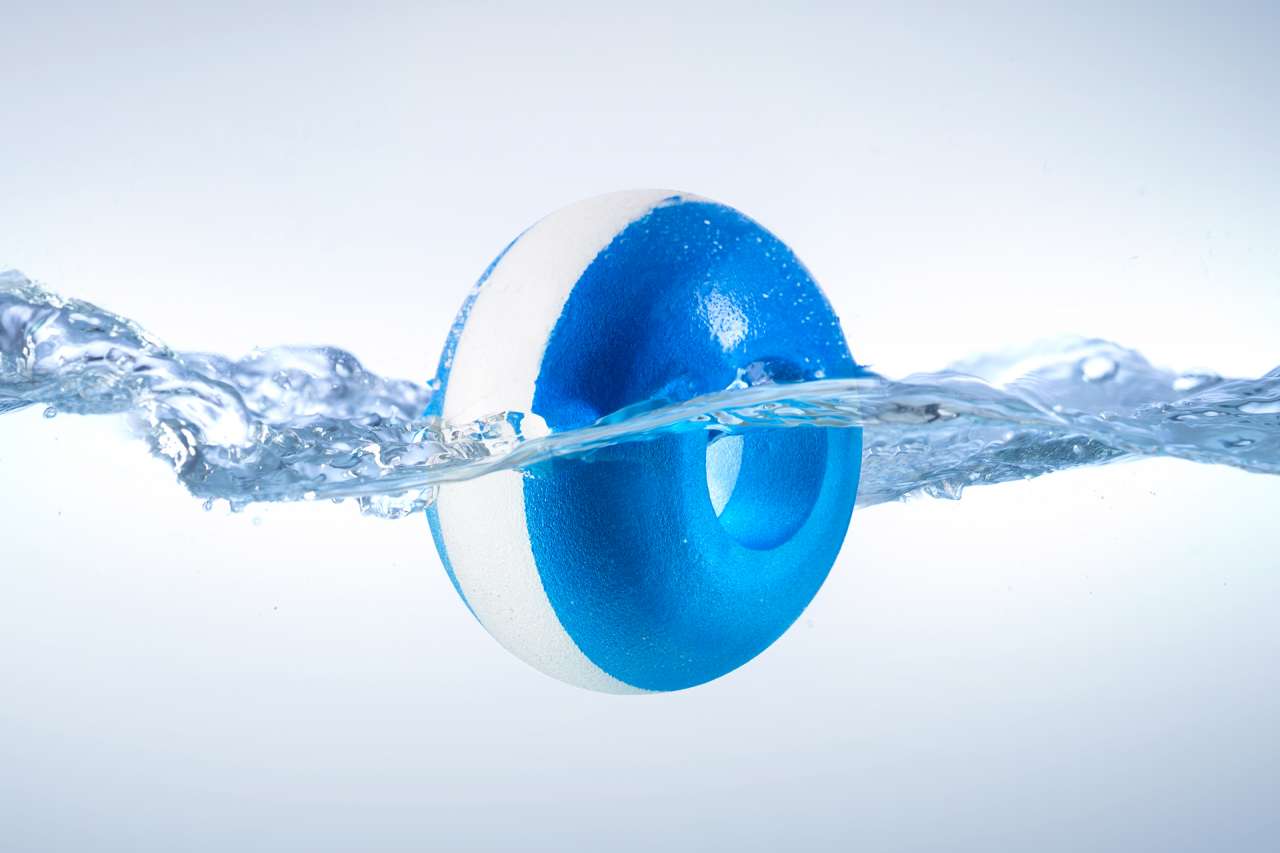

Cellular polyethylene is one of the most versatile and cutting-edge cellular materials in terms of application and processing quantity. That is why we produce and sell an enormous range of PE types including cross-linked polyethylene foams with various densities and in many colours and various degrees of softness.

KÖPP also offers electrically conductive, anti-static and fire resistant qualities of cellular polyethylene. The range includes metallocene qualities, a unique polyamide foam and PE and EVA blends.

Areas of application

Cellular polyethylene – the material

All our cellular polyethylene qualities combine the positive properties of a plastic: high ageing stability, high chemical resistance, low emission values, exceptionally uniform density, they are odour-free and suitable for hot forming processes. It comes as no surprise that the possible applications for polyethylene are almost unlimited: from automotive engineering and the packaging sector to countless industrial applications, medical technology and orthopaedics.

In order to meet all our clients’ needs, we offer polyethylene in different qualities, densities and block sizes, and in selected blends. We can supply you the material as blocks, sheets or rolls, processed into strips or punched, moulded or milled parts, with or without a self-adhesive coating.

You can download our data sheets on cellular polyethylene from our Service Centre.

Technical data

- A variety of densities (from 18 kg/m³ up to 400 kg/m³))

- Low heat conducting values (approx. 0.04 W/mK)

- High resistance to chemical corrosion

- Low fogging. Non-allergenic

- High ageing stability

- Suitable for hot-forming processes

- Highly fire resistant (FR)

- Coloured version also available

- Electrically conductive or anti-static versions available

- Easy to work

- Cost-effective

- High temperature resistance

Materials

CN & SD

With K/PE40CN and K/PE40SD we offer the electronics industry in particular, tailor-made solutions. Our block foam products do not only protect against impacts and vibrations. When it comes to packaging voltage-sensitive electronic components, the choice between antistatic and conductive properties is an important criterion when choosing the right material. Our SD is the right choice for all components that are not allowed to charge themselves electrically.

For example, with sensitive circuit boards that would be defective at the moment they are exposed to a high electrical voltage. Our CN qualities can also function statically dissipative, and they are also electrically conductive due to their lower resistance. Thus CN protects the component against uncontrolled discharge, e.g. with LED headlights.

FR

With K/PE30FR, K/PE35FR and K/PE45FR we are offering flame-retardant qualities in densities of 35 and 45 kg/m³. These are especially suitable for technical applications, such as in the automotive and aerospace industries. Compliance with certain values and standards plays an important role.

We are currently working actively on developing a new FR quality with a density of only 24 kg/m³, which is also halogen-free.

Automotive

With K/PE30A, K/PE35A and K/PE35AT we offer special developments especially for the automotive industry and other branches of industry such as the sanitary and electrical industry. The end product is thermoformed polyethylene moulded parts, which are used, for example, in the car bodywork for sealing purposes.

An important

prerequisite for this is a material that can be easily formed and which

optimally combines the required sealing properties with the necessary flow

properties.

EVA

EVA is a closed-cell, cross-linked EVA, available with densities ranging from 30 kg/m³ to 400 kg/m³. EVA foams are more tough and elastic than LDPE foams and they are often used in the area of sports and leisure.

Unlike other manufacturers, ours is a 100% EVA grade. Now available also in different colours. One of the features of this material is that it has a high return rate (i.e. a low compression set).

Blue Angel

With K/PE30, we have a PE block foam in our portfolio that meets the strict requirements of the BLUE ANGEL environmental standard. Our K/PE30 was therefore awarded the BLUE ANGEL certification. Special emphasis is placed on demanding tests of low emissions and pollutants. Currently, KOEPPCELL® K/PE30 is the only PE block foam in the world to receive this award.