Reliable quality

Filtering and ventilating

With its high-quality materials and equipment, KÖPP offers you a wide range of options for filtering or ventilating solid, liquid or gaseous media. We use porous sintered plastics with various pore widths from 5-200 my.

With our unique VYON® and GURON filter materials® we can enable you to find truly bespoke solutions for liquid filtration, depth filtration, ventilation, soundproofing or dust filtration. There is a reason why our filter materials are used in virtually all sectors of industry, and increasingly in the home.

Filtering/separating

The porous structure of our filter materials is perfect for depth filtration into different filtration ratings. The plastic is also suitable for formed parts for truly bespoke solutions, and the material properties can be individually adjusted. This means our products are used for a huge range of applications:

- Drinking water filtration (e.g. domestic water filtration)

- Process water filtration

- Air filtration, e.g. for electronic devices (e.g. inhalators)

- Oil filtration

- Laboratory equipment

Ventilation and venting

The porous structure of our filter materials also has vital advantages for ventilation and venting: They allow air through but reliably stop solids. Different qualities are also available for bespoke problem solutions to deal with overpressure or underpressure.

An important point for many customers: Our materials have been tested in accordance with UL-94 and IP classes.

- Battery ventilation and flame protection in vehicles

- Ventilation of electric motors in vehicles (for headlights or windscreen wipers) in industry and medicine

- Ventilation and venting of containers / canisters with media residues in industry and medicine

- Water and oil-repellent venting for geared engines

- Ventilation of liquids (diffusion ventilation) such as for water in aquariums, fish ponds or for industrial liquid waste

- Silo ventilation for an even flow of powder media (sugar, flour, concrete etc.) and for conveying solids

Spraying

The fine structures of the sintered plastic allow even distribution of liquids. This property is very useful for spraying liquids for air humidifiers (e.g. at fresh vegetable counters). This also applies for nasal spray pumps or fragrance sprays.

Protection

For simultaneous ventilation our filter materials offer protection against splashing water and contamination by dust. Our customers can also benefit from individual moulding options

- Dust protection for sensor equipment

- Dust protection for electric motors at the suction opening

- Splash protection for sensors (extra-hydrophobic versions are available here)

- Protection against dust and splashing water for housing openings

Soundproofing

Noise is a danger to health. For this reason noise reduction is an important part of work safety. Thanks to their porous structure, our materials VYON® and GURON® are highly suited to soundproofing, reducing noise by up to 30 dB.

As well as our standard soundproofing, we can also offer you bespoke solutions, as the forming can be adapted to suit your precise application.

- Standard soundproofing for pneumatic systems with BSP thread

- Noise reduction in pneumatic artificial joints (medicine)

- Noise reduction in electronic devices

- Noise reduction for electronic motors (e.g. lawn mowers, chainsaws, electric tools)

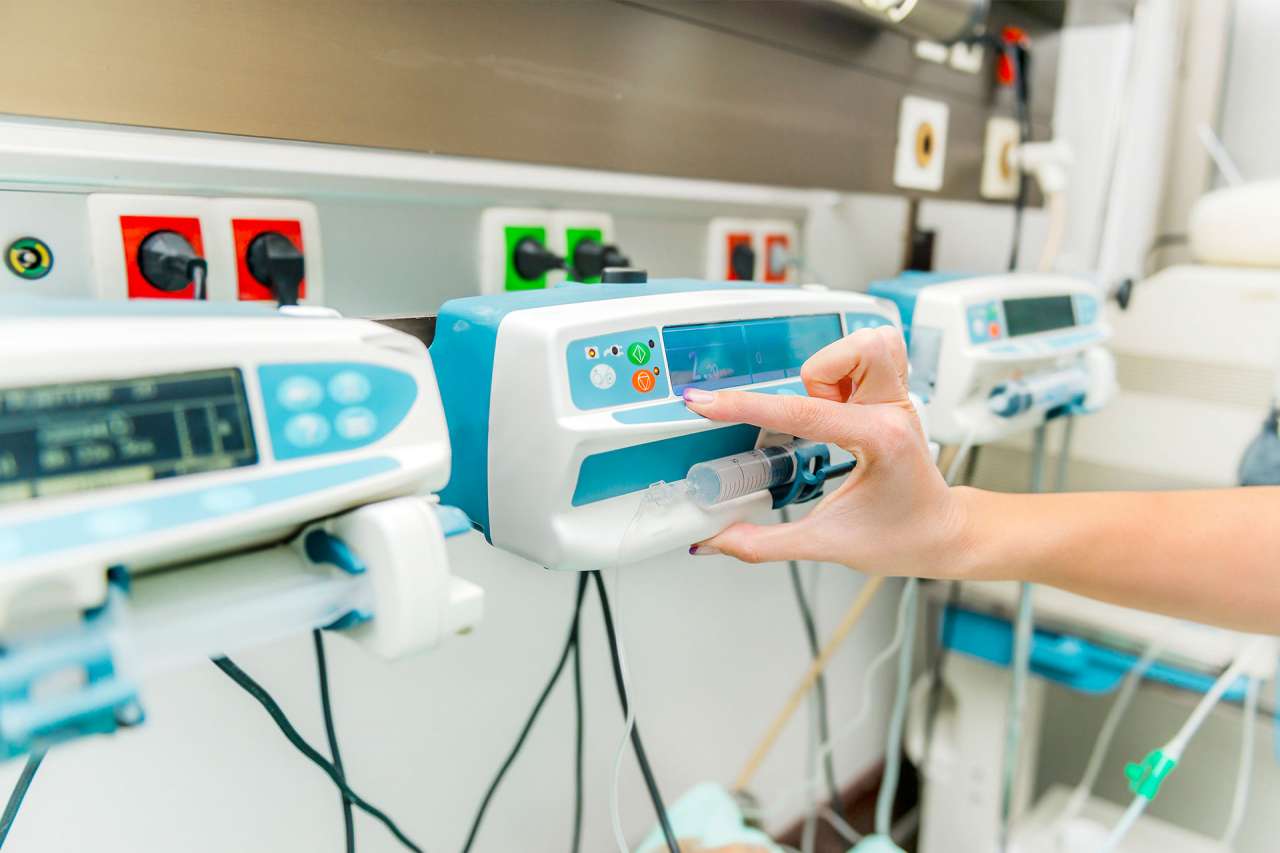

Medical technology

BioVyon™

Unlike other sectors, medical technology makes very different demands on the material in terms of purity or durability. At KÖPP our customers can choose from sintered plastics, which can be produced in ISO clean rooms upon request – we observe the CGMP process and we already have ratings for various certifications, including USP Class VI.

Vyon® materials also have further benefits such as excellent chemical resistance and durability. Our BioVyon™ materials have a low biological load, extremely low extractables and minimal particle detachment.

- Solid phase extraction and chromatography column frits

- Solid extraction and chromatography resins

- Medical device filtration

- Venting of maintenance and pharmaceutical devices

- Diagnostics

- Catheter venting

- Antibody cleaning