Geometrías de ranura

Aquí encontrará directrices de diseño y notas sobre el diseño de ranuras, así como información sobre la aplicación de juntas en diversas condiciones de superficie y con nuestros respectivos sistemas.

This section contains design guidelines and recommendations on notch design (optimum design and negative examples), and recommendations on applying seals to even surfaces with dual-component systems.

Optimum

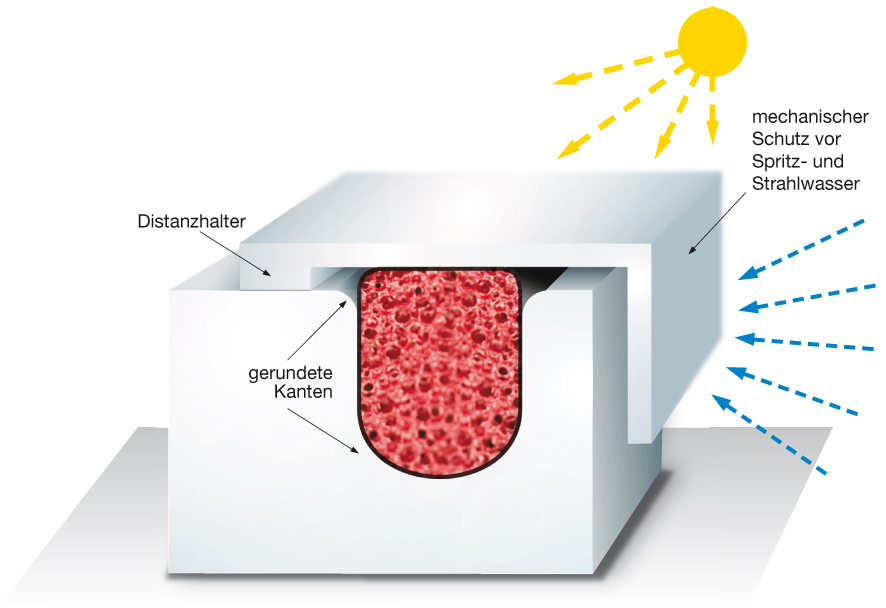

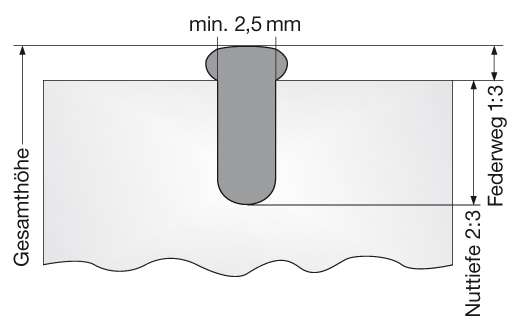

Optimum design of notch geometry for application of liquid sealing components

Negative

Negative examples of notch design to avoid air pockets

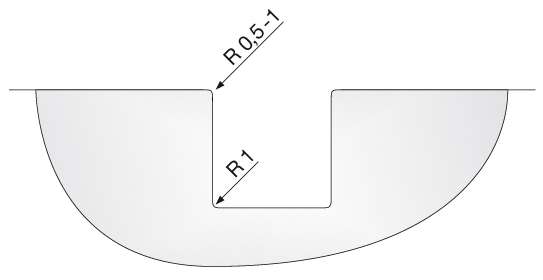

A Avoid corners – Better: RADII

B Avoid recessed notch cross-sections if possible

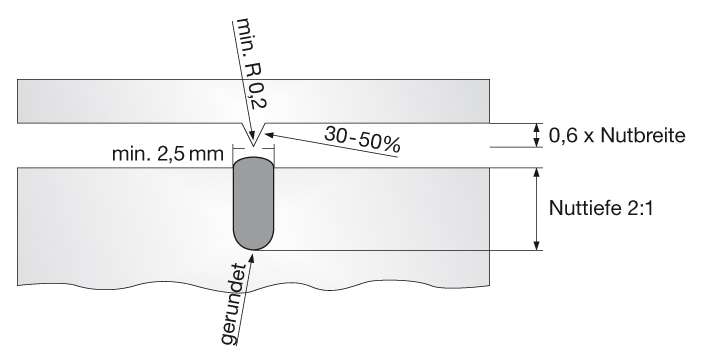

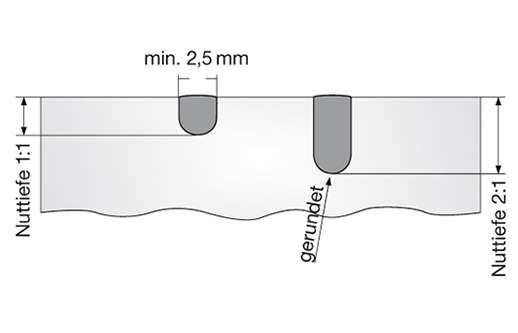

C Notch widths> 3 mm no problems

< 3 mm problems(special nozzles, production losses)

D Notch depth: not too large for small notch widths

e.g.: W=3 / D=3 (special nozzles, production losses)

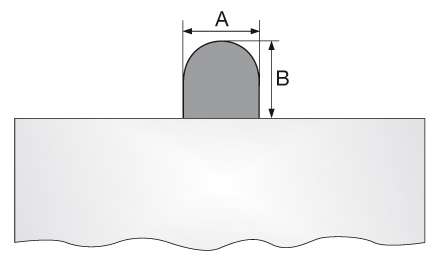

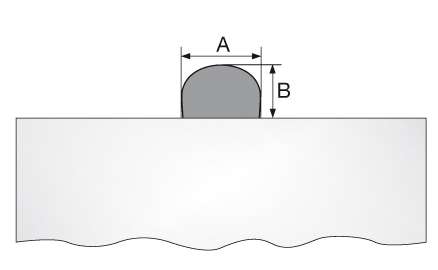

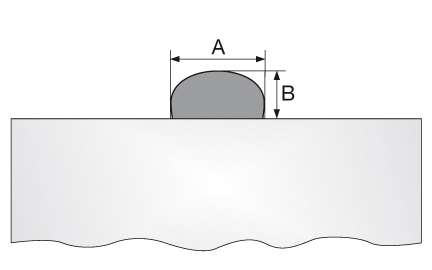

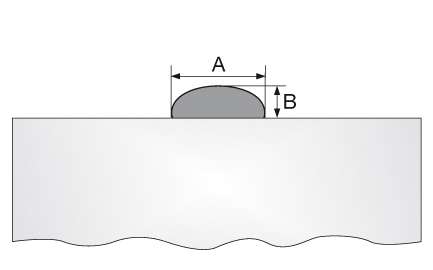

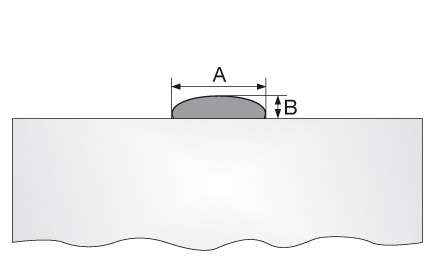

Seal application on even surfaces

1. Difficult to implement, only possible with ultra-thixotropic material and special application equipment.

2. For markedly 3-dimensional or overhead application up to an angle of 70°.

3. Only just possible with liquid material.